EVGA GeForce GTX 1080 iCX FTW2 Review: Everything Detected, More Than Just A Cooler

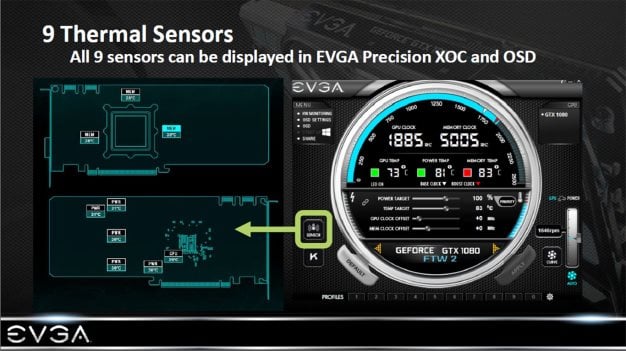

All told there are 9 additional sensors and a microcontroller unit integrated in the PCB on cards featuring iCX technology. And of course, there’s also a sensor in the GPU, for 10 in total. To date, graphics cards have been using a single sensor in the GPU to determine a card’s temperature, but because GPUs have gotten more efficient and less power hungry over the years, they may not be the hottest running component on a graphics card any longer, and as such, may not be the best indicator of overall card temperature.

The sensors on EVGA’s iCX cards are distributed throughout the memory and components in the voltage regulation circuitry on the front and back of the cards. Readings from the sensors can be displayed in EVGA’s XOC utility (including in the hardware monitor section) and are used to present data to end users and ultimately determine the fan speeds on the cards.

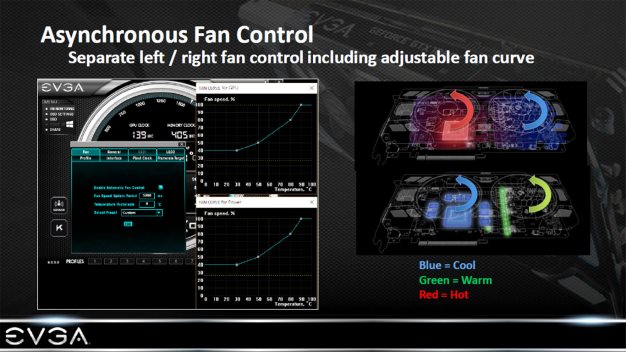

We should also note that the fans are controlled asynchronously now. If the GPU is getting toasty, the GPU fan will spin up; same for the VRM/memory fan. Now that there’s additional sensors on board, it’s no longer the GPU temp alone that determines fan speed. The fan curves for the individual cooling fans can also be tweaked manually, for those that link to tinker or want to keep certain components running cooler than stock. Controlling the fans asynchronously can also potentially reduce noise output. Two fans spinning at same speed, creating similar tones and frequencies, will tend to double the perceived noise output. When running fans asynchronously, however, the louder of the two fans will tend to drown out the quieter one.

The cooler on iCX cards has also been optimized in quite a few ways. Both base and back-plates on the cards are die-cast and form fitted to make contact with vital components. Thermal pads are installed where necessary as well. There are also pin fins in strategic areas of the baseplate where there is clearance, to increase surface area and cooling capacity.

The card's heatsinks and heat-pipes got some special treatment too. Some of the heatsink fins are L-shaped to make better contact with the heat-pipes, and they’re positioned to allow 50% more air to pass through as well. Holes in the fins also allow air to flow through them, so there is less bounce-back from air hitting the base-plate and re-bounding back up through the heatsink.

All told, the cooler is able to better cool all of the components on the card. Even the back of the PCB ends up significantly cooler. In a side-by-side comparison, the back of an iCX-equipped FTW2 card was over 10’C cooler than an original FTW card with ACX 3.0 cooling.

Along with all of the new sensors and optimized cooler, EVGA integrated a safety fuse on the cards as well, to add another layer of protection. Should too much power be pumped into the card for whatever reason, the fuse will blow and protect vital components. The card will not function when the fuse blows, but it’s a quick repair that EVGA can turn around in a short time.

Like other high-end EVGA graphics cards, all of the LED lighting on the iCX-branded cards is RGB and fully customizable. But there are also new lighted G, P, and M indicators that can either be lit to match the rest of the card, or provide indicators based on temperature. The colors can be set for low, medium, and high temperatures (all fully customizable), so you can quickly glance at the card and get an idea as to how hot or cool the various areas are running.