3D Chip Inventor BeSang Claims New NAND Flash Tech Will Offer Insane 2 Cent Per Gigabyte Costs

At some point in time, solid state drives (SSDs) are likely to finally supplant mechanical hard disk drives (HDDs) just as USB thumb sticks replaced floppies, but it won't happen until the cost of NAND flash memory drops even further, paving the way for parity in terms of price-per-gigabyte. It may even happen sooner than later—BeSang Inc., inventor of 3D monolithic chip technology in 2010, claims to have found a way to reduce the cost of 3D NAND from over 20 cents per gigabyte to just around 2 cents per gigabyte.

The path to cheaper 3D NAND lies in shrinking the cell size of the overall structure, which BeSang calls a "fundamental problem" of Samsung's approach to 3D NAND flash memory.

"Samsung’s most advanced 3D NAND stacks up to 48 layers of memory cells in the vertical direction. Therefore, we would expect that 48-layer 3D NAND should be cheaper than planar NAND. Ironically, 3D NAND is still expensive compared to planar NAND," said Sang-Yun Lee, CEO of BeSang. "Their fundamental problem is the gigantic cell size of their 3D NAND."

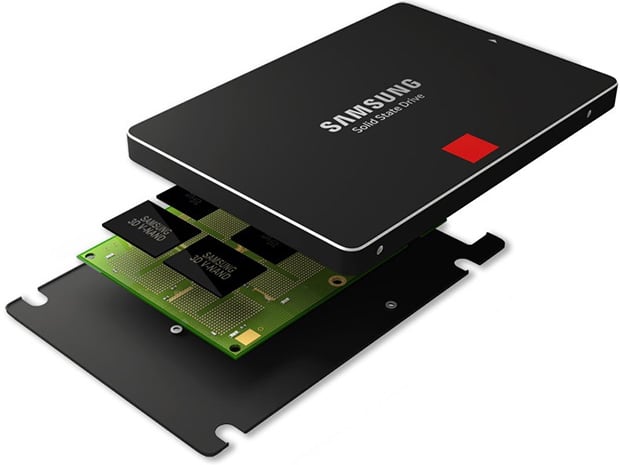

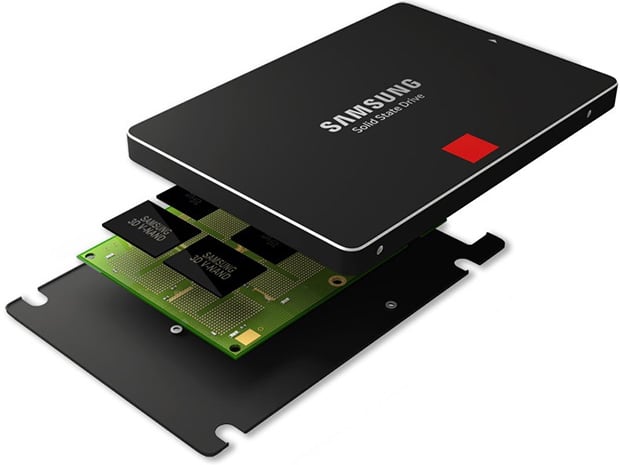

Advances in 3D NAND technology could lead to lower cost SSDs

As currently implemented, the cell size of 3D NAND is around 10 times bigger than planar 2D NAND. That's because over 60 percent of the structure is used for three functions, those being control logic (34 percent), a tungsten isolation slit (20 percent) and a word-line staircase (26 percent). BeSang's solution is to place all of the control logic on the bottom layer, which would free up the top area for vertically stacking memory cells.

In addition to reducing the cell size, BeSang claims to have a better method than Samsung and other 3D NAND flash memory players at implementing the staircase world-line architecture. It also claims faster processing less expensive equipment than the competition.

"With just five masks, we can process our 3D NAND with three-times the capacity of SanDisk's or Samsung's designs in just five days processing, whereas it takes them as much as 10 weeks to process their 3D NAND chips," Lee adds. "The capital equipment we need also costs as much as 10-times less than theirs."

BeSang is currently looking to partner to 3D NAND memory houses and is also open to manufacturing chips for resale by others.

The path to cheaper 3D NAND lies in shrinking the cell size of the overall structure, which BeSang calls a "fundamental problem" of Samsung's approach to 3D NAND flash memory.

"Samsung’s most advanced 3D NAND stacks up to 48 layers of memory cells in the vertical direction. Therefore, we would expect that 48-layer 3D NAND should be cheaper than planar NAND. Ironically, 3D NAND is still expensive compared to planar NAND," said Sang-Yun Lee, CEO of BeSang. "Their fundamental problem is the gigantic cell size of their 3D NAND."

Advances in 3D NAND technology could lead to lower cost SSDs

As currently implemented, the cell size of 3D NAND is around 10 times bigger than planar 2D NAND. That's because over 60 percent of the structure is used for three functions, those being control logic (34 percent), a tungsten isolation slit (20 percent) and a word-line staircase (26 percent). BeSang's solution is to place all of the control logic on the bottom layer, which would free up the top area for vertically stacking memory cells.

In addition to reducing the cell size, BeSang claims to have a better method than Samsung and other 3D NAND flash memory players at implementing the staircase world-line architecture. It also claims faster processing less expensive equipment than the competition.

"With just five masks, we can process our 3D NAND with three-times the capacity of SanDisk's or Samsung's designs in just five days processing, whereas it takes them as much as 10 weeks to process their 3D NAND chips," Lee adds. "The capital equipment we need also costs as much as 10-times less than theirs."

BeSang is currently looking to partner to 3D NAND memory houses and is also open to manufacturing chips for resale by others.